Australian Fire Hydrant Testing Requirements Explained

Quick Summary

Hydrant testing is one of the most misunderstood parts of fire compliance. Drawing on Australian standards and real on-site experience, this article breaks down how often fire hydrants need to be tested, what’s required at each stage and how building owners can ensure ongoing compliance.

Table Of Contents

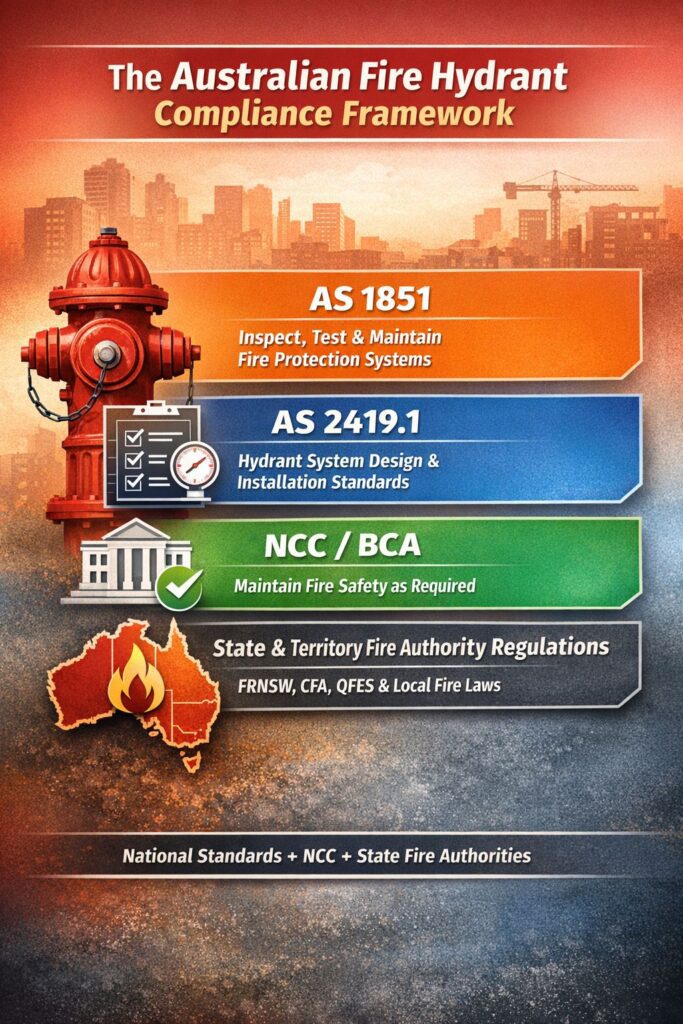

In Australia, the “how often” question is answered primarily by AS 1851, with design intent and acceptance criteria informed by AS 2419.1 and overarching duties under the National Construction Code (NCC/BCA). State legislation and local fire authorities then sit over the top. Where those layers intersect, clarity and good records matter.

A Summary Of The Australian Compliance Framework

Fire hydrant testing in Australia sits within a layered compliance framework. Understanding how these pieces fit together is essential to interpreting test results correctly and maintaining defensible compliance.

- State/territory fire legislation – and fire authority requirements (e.g., FRNSW, CFA, QFES) may add reporting or interface expectations, especially after alterations or incidents.

- AS 1851 – tells you how often to inspect, test and maintain fire protection systems, including hydrants, and what to check at each interval.

- AS 2419.1 – sets out how hydrant systems are designed and installed (coverage, flows, pressures, outlets). It’s critical when interpreting test results—because you’re checking performance against the design intent.

- NCC/BCA – requires that fire safety measures be maintained so they operate as intended. In practice, that means following AS 1851 unless an approved alternative applies.

Why Fire Hydrant Testing Matters In Practice

Fire hydrant testing is often treated as one of the more routine parts of fire compliance. The irony is that hydrants are also one of the few systems relied on directly by responding firefighters. When a brigade arrives on site, they expect immediate access to water, adequate pressure and enough flow to support suppression operations. If any of those elements fail, the consequences escalate quickly.

In real incidents, hydrant failures rarely come down to dramatic design flaws. They are usually the result of gradual deterioration, missed inspections, or seemingly minor issues that were never rectified. That is why regular, standards-based testing is critical, not just to satisfy compliance requirements, but to ensure the system will actually perform under pressure.

How Often Do Fire Hydrants Need To Be Tested?

From a practical perspective, most fire hydrant systems in commercial, industrial and multi-residential buildings are subject to a six-monthly inspection regime. These inspections form the backbone of ongoing compliance and are designed to identify issues early, before they compromise system performance.

Beyond routine inspections, hydrant systems must also undergo performance testing at specific points in their lifecycle. This includes testing at commissioning, after significant system modifications, and periodically thereafter as required by AS 1851 or where performance degradation is suspected. The exact frequency of flow testing can vary depending on system type, building use and documented maintenance history.

Ready To Discuss Your Requirements?

Our Experts Look Forward To Hearing From You!

Six-Monthly Fire Hydrant Inspections – What Is Checked

Six-monthly inspections focus on condition, accessibility and operability rather than high-stress performance testing. Technicians will typically examine internal and external hydrant outlets to confirm they are visible, clearly identified and unobstructed. Caps, chains and threads are checked for damage or corrosion, and valve operation is verified to ensure hydrants can be opened without difficulty.

These inspections are also where many real-world compliance issues are identified. In active buildings, hydrants are often partially blocked by storage, concealed behind new walls, or made inaccessible by changes to car park layouts. External hydrants are particularly vulnerable to impact damage, corrosion and missing components, especially in coastal or industrial environments.

While these issues may appear minor, any delay or obstruction during an emergency can severely limit firefighting effectiveness.

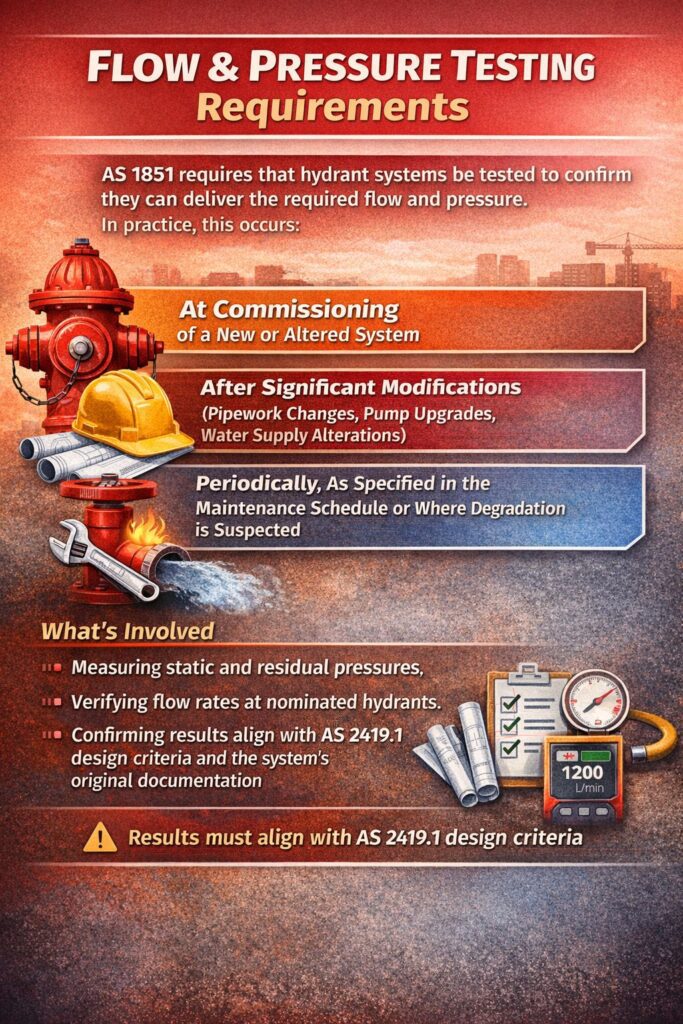

Flow & Pressure Testing – Verifying System Performance

Flow testing is where hydrant compliance moves beyond appearance and into measurable performance. During a flow test, static and residual pressures are measured, and flow rates are assessed to confirm the system can deliver the water volume required under AS 2419.1 design criteria.

Flow testing is mandatory when a hydrant system is first commissioned and after any significant modification, such as alterations to pipework, pumps or water supply connections. It may also be required periodically, where specified by AS 1851 or where declining performance is suspected.

A hydrant that looks compliant but cannot sustain adequate flow under load presents a serious risk to both occupants and responding firefighters. Flow testing provides objective evidence that the system can perform its intended function, not just meet a visual checklist.

Long-Term Performance & Aging Infrastructure

As buildings age, hydrant system performance can degrade gradually and often unnoticed. Changes to municipal water supplies, internal corrosion, partial blockages or incremental building modifications can all reduce available pressure over time.

This is where trend analysis becomes important. Comparing flow and pressure results over successive tests can reveal early warning signs long before a system fails outright.

Addressing these issues early is almost always more cost-effective than waiting for a non-compliance notice or emergency failure.

Record-Keeping Obligations Under AS 1851

Testing alone is not enough. AS 1851 requires that inspection, testing and maintenance records be kept and made available for review. In practical terms, this means maintaining a clear, traceable history showing what was tested, what defects were identified, and how and when those defects were rectified.

Inadequate record-keeping is one of the most common compliance failures we encounter. Records are often lost during changes in managing agents, left incomplete after defect rectification, or scattered across multiple contractors. From a regulatory or insurance perspective, missing records can be interpreted as missed maintenance, regardless of what actually occurred on site.

Common Fire Hydrant Defects We Identify During Testing

Across a wide range of buildings, the same defects appear time and again. Hydrants are frequently found obstructed by storage or fit-outs, valves are seized due to lack of regular operation, and external outlets show advanced corrosion or impact damage. In some cases, unapproved modifications to pipework or outlets reduce system effectiveness without anyone realising.

These defects rarely appear overnight. They develop gradually, which is exactly why regular inspections and performance testing are built into the Australian standards framework.

Ready To Discuss Your Requirements?

Our Experts Look Forward To Hearing From You!

Responsibilities of Building Owners, Strata & Facility Managers

Ultimate responsibility for fire hydrant testing rests with the building owner or, in strata schemes, the owners’ corporation. While facility and strata managers often coordinate inspections and contractors, accountability does not transfer.

Clear communication, realistic budgeting and an understanding of what the standards actually require are essential. After refurbishments or tenancy changes, it is particularly important to confirm that hydrant coverage and performance have not been compromised.

State Variations & Fire Authority Expectations

Although AS 1851 is nationally referenced, local fire authorities may impose additional requirements, particularly following major works or incidents. These can include expectations around test witnessing, documentation formats or connection compatibility. Confirming local authority expectations is especially important for complex or high-risk buildings.

Final Thoughts

Fire hydrant testing is about ensuring that a critical firefighting system will work when it is needed most. Regular inspections, appropriate performance testing and clear records form the foundation of reliable compliance.

When those elements are in place, hydrant systems tend to perform as intended. When they are not, failures are often discovered at the worst possible moment.

LIKE TO KNOW MORE?

Schedule A FREE Discovery Call

Frequently Asked Questions (FAQ)

A: Most building hydrant systems require six-monthly inspections and periodic flow testing in accordance with AS 1851-2012, plus testing at commissioning and after significant changes.

A: Not always annually. Flow testing is mandatory at commissioning and after alterations, and periodically thereafter as specified by AS 1851-2012, or the system’s maintenance schedule.

A: Generally, the building owner or owners corporation is responsible, often delegating coordination to a facility or strata manager.

A: If a residential building is equipped with a fire hydrant system, it must be maintained and tested in line with AS 1851-2012, regardless of occupancy type.

A: Defects must be recorded, assessed and rectified within an appropriate timeframe. Continued non-compliance can expose owners to regulatory action and insurance risk.

A: Yes. AS 1851-2012 requires maintenance records to be kept on site or readily accessible for inspection by authorities.

Important Disclaimer: This article is general in nature and does not constitute legal or building compliance advice. Always consult a licensed fire safety practitioner and review relevant legislation for your property classification.

References:

Request a Free Quote

Get a no-obligation quote today—fast, easy, and completely free!