How To Achieve & Maintain Compliance Protecting People, Property & Your Insurance

Quick Summary

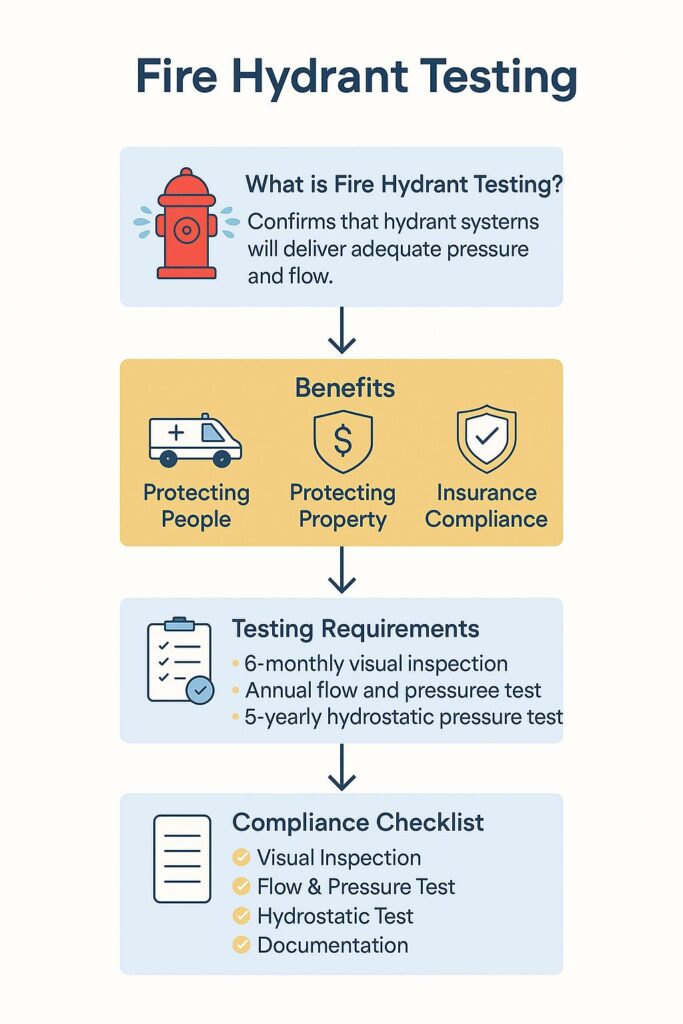

Fire hydrant testing is not just about ticking a box, it’s about saving lives, property, reputations and money. This article walks you through why it’s essential, what the rules are, what the tests involve, how regular maintenance saves money, reputation and most importantly lives.

Table Of Contents

When it comes to fire safety, fire hydrants are the unsung heroes, but without regular testing and maintenance, they can become liabilities, risking lives, leaving property exposed, even invalidating insurance.

What Is Fire Hydrant Testing & Why Does It Matter?

Fire hydrant testing is a proactive process that confirms your hydrant system will deliver sufficient pressure and flow when it matters.

According to Australian Standard AS 1851‑2012 (Section 4), building hydrants require:

- 6‑monthly visual & physical inspections

- Annual flow and pressure testing

- 5‑yearly hydrostatic pressure testing to ensure pipework integrity

Under AS 2419.1‑2021, hydrants must deliver a residual pressure of 150–200 kPa and flow of at least 10 L/s to support effective firefighting operations.

Fire brigades in NSW expect hydrants to be no more than 100 metres apart in residential areas, depending on the lay of the land and provision of other services such as phone lines, power and gas, according to Fire and Rescue NSW, ensuring fast access in emergencies.

Protecting People & Saving Lives

In a fire emergency, every second matters. Fire hydrants are often firefighters’ first point of contact with your building’s water supply.

- Fire and Rescue NSW responded to over 130,000 incidents in 2022–23, including more than 68,000 fire-related calls

- In NSW rural areas, the Rural Fire Service attends approximately 30,000 incidents per year with over 70,000 volunteers

In such incidents, hydrant reliability is key. Systems with blocked valves, corrosion, or pressure loss can delay critical firefighting operations, risking lives, injury, and escalation of damage.

That’s why the 5‑year hydrostatic flow test is a non‑negotiable safeguard, as it catches system degradation before it’s too late.

Protecting Property & Avoiding Losses

A reliable fire hydrant system can significantly reduce property damage. Fires in commercial and residential buildings can cost millions and in Australia, insurance claims make up a staggering portion of that.

- In a 2023 audit by NSW Fair Trading, they discovered over 50% of the new buildings audited for fire safety standards had defective fire safety systems, including several with specific issues caused by faulty or missing fire hydrant systems, which has resulted in an increased focus by the government on fire hydrant system compliance.

- During the Black Saturday bushfires, the Insurance Council of Australia reported $1.2 billion in property/content claims, comprising 84% of total payouts

- Although those were extreme bushfires, property fires remain among the most common emergencies across the country, over 140,000 fire‑related incidents were attended in 2021–22 alone

In many cases, under‑performing hydrants have contributed to fires spreading more rapidly. Insurers are increasingly scrutinising maintenance records and a missing or out-of‑date flow test can often lead to denied claims or inflated premiums.

Why Insurance Compliance & Testing Is Non‑Negotiable

Insurers in Australia expect strict compliance with both standards and regulations. CGU’s Risk Awareness Guide [insert link] highlights that fire hydrant systems require proactive maintenance, not reactive fixes, to avoid non-compliance penalties or voided insurance.

Key compliance requirements:

- AS 1851‑2012 mandates inspection and testing intervals (6‑monthly, annual, 5‑yearly)

- AS 2419.1‑2021 sets benchmarks for water pressure, flow, and spacing between hydrants

Missing or incomplete documentation can raise red flags during insurance assessments or compliance audits. Insurers may request certificates showing:

- Flow rate and pressure readings (in kPa and L/s)

- Static and residual pressure measurements

- System pass/fail conclusion

- Technician name, testing date, and compliance reference

Ready To Discuss Your Requirements?

Our Experts Look Forward To Hearing From You!

What Testing Involves & The Compliance Lifecycle

6 Monthly Visual Inspections

- Hydrants must remain visible, clearly marked, and unobstructed

- Caps and outlets should be free from debris, vegetation, or damage

- Valves, threads, and markers should function properly

Annual Flow & Pressure Test

- Measure static pressure and residual pressure under flow

- Confirm minimum requirements from AS 2419.1 are met: 150–200 kPa residual, ≤ 10 L/s flow rate, etc.

- Provide a formal flow test report

5 Year Hydrostatic Pressure Test

- Applies pressure beyond normal operating levels to assess the system’s structural integrity

- Detects hidden leakage, blockages, or pipework deterioration

- Essential for continued compliance under both AS 1851‑2012 and insurer expectations

Making Your Site Compliant – A Practical Checklist

| ACTION | FREQUENCY | REQUIREMENTS |

| Visual & Accessibility Checks | Every 6 months | Inspect hydrants for damage, rust, leaks, ensure clear signage and unblocked access. Involves documentation of visible issues and immediate remedy advice. |

| Flow & Pressure Test | Annually | Measure static and residual pressure plus flow rate results benchmarked against AS 1851 criteria. Report highlights hydrants failing to meet performance thresholds. |

| 5‑year Hydrostatic Integrity Test | Every 5 years | Pressure test valves, pipes, and seals under full operating conditions, inspect for hidden corrosion or leaks. Replace worn components, lubricate mechanisms, certify system integrity. |

| Signage & Clearance Verification | Ongoing | Confirm signage remains intact and readable, hydrants are free of visual obstruction, access routes open, especially after site changes or landscaping. |

| Upgrade To AS 2419.1–2021 Design Spec | One-off / during renovations | If hydrant systems were installed before 2021, ensure current components meet updated flow, materials and signage requirements. May require retrofit or upgrade. |

| Accurate Documentation Management | After each test | Maintain compliant reports and asset records to satisfy AFSS audits and insurer requirements. Missing records can jeopardise insurance claims. |

The Bigger Picture – Climate Change, Fire Risk & Regulatory Landscape

Australia is facing increasing fire risk driven by climate change. The Bureau of Meteorology / CSIRO 2018 “State of the Climate” report confirms more severe fire weather is becoming the norm.

In response, both Standards Australia and Australian fire authorities are updating guidelines (e.g. AS 2419.1‑2021) to support more resilient infrastructure.

Meanwhile, major insurers (like CGU, IAG) are pushing for stricter loss prevention protocols, especially in high-risk zones.

That makes your hydrant system not just a legal requirement, but a strategic asset in risk mitigation.

Taking Action – How To Move Forward

- Review your hydrant testing records:

- When was your last annual flow test?

- When is your next 5‑year hydrostatic test due?

- Schedule missing inspections or tests right away

- Confirm that test reports include all essential data: pressure, flow, technician name, site address, pass/fail, dates

- Keep testing records on file for audit or insurance purposes

- Partner with a trusted provider like Asset & Fire to manage the entire process seamlessly

Closing Thoughts – It’s More Than Maintenance It’s Your Shield

Fire hydrant testing isn’t just a bureaucratic hurdle, it’s about protecting life, minimising asset damage, staying insured, and meeting the law. Regular inspections, accurate testing, thorough reporting, which when done properly, keep your business safe, compliant, and resilient.

At Essential Asset & Fire, we help you navigate all this on time, in full, and stress‑free.

Frequently Asked Questions (FAQ)

A: Fire hydrant testing is the process of confirming that your hydrant system can deliver the correct water flow and pressure during an emergency. It involves visual inspections, flow and pressure testing and hydrostatic integrity tests as required by Australian

A: Under AS 1851:2012, visual and accessibility inspection every 6 months, flow and pressure test annually and hydrostatic pressure test for system integrity every 5 yrs

A: Many insurers require proof of compliance with AS 1851 and AS 2419.1. Missing tests or incomplete records can lead to claim denial, higher premiums & non-compliance penalties

A: If installed before 2021, systems may need upgrades to meet current AS 2419.1 specifications for flow, materials, and signage. Retrofitting may be required

A: With more extreme fire weather predicted by the Bureau of Meteorology and CSIRO, hydrant reliability is more critical than ever. Standards and insurer requirements are tightening to address increased fire risks

GET IN TOUCH

Schedule A FREE Discovery Call

Important Disclaimer: This article is general in nature and does not constitute legal or building compliance advice. Always consult a licensed fire safety practitioner and review relevant legislation for your property classification.

References:

Request a Free Quote

Get a no-obligation quote today—fast, easy, and completely free!